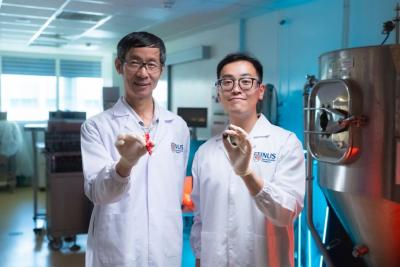

Các kỹ sư của NUS đã tạo ra một bộ gắp robot lai có thể kẹp được nhiều loại vật thể

Inspired by the natural dexterity of the human hand, a team of engineers from the National University of Singapore (NUS) has created a reconfigurable hybrid robotics system that is able to grip a variety of objects: from the small, soft and delicate to the large, heavy and bulky. This technology is expected to impact a range of industries, involving food assembly, vertical farming and fast-moving consumer goods packaging, which will progressively automate more of their operations in the coming years.

Inspired by the dexterity of a human hand, the NUS team has developed a hybrid robotic gripper which can be reconfigured on demand to pick and place a wide range of delicate food items.

Led by Associate Professor Raye Yeow from the NUS Department of Biomedical Engineering and the NUS Advanced Robotics Centre, the hybrid robotic grippers use soft, flexible 3D-printed fingers with a reconfigurable gripper base. The robotic innovation is now in the process of being brought to commercial partners under the team’s start-up RoPlus (RO+), comprising NUS researchers Low Jin Huat, Khin Phone May, Chen Chao-Yu and undergraduate student Han Qian Qian.

“An object’s shape, texture, weight and size affect how we choose to grip them. This is one of the main reasons why many industries still heavily rely on human labour to package and handle delicate items,” Assoc Prof Yeow said. “Our hybrid robotic gripper technology revolutionises traditional pick-and-place tasks by offering advanced capabilities that allow robots to safely interact with delicate items of various shapes, sizes and stiffness, just like the human hand.”

Xem chi tiết tại đây