Các nhà phát minh của NUS sản xuất tăm bông mũi họng để kiểm tra COVID-19

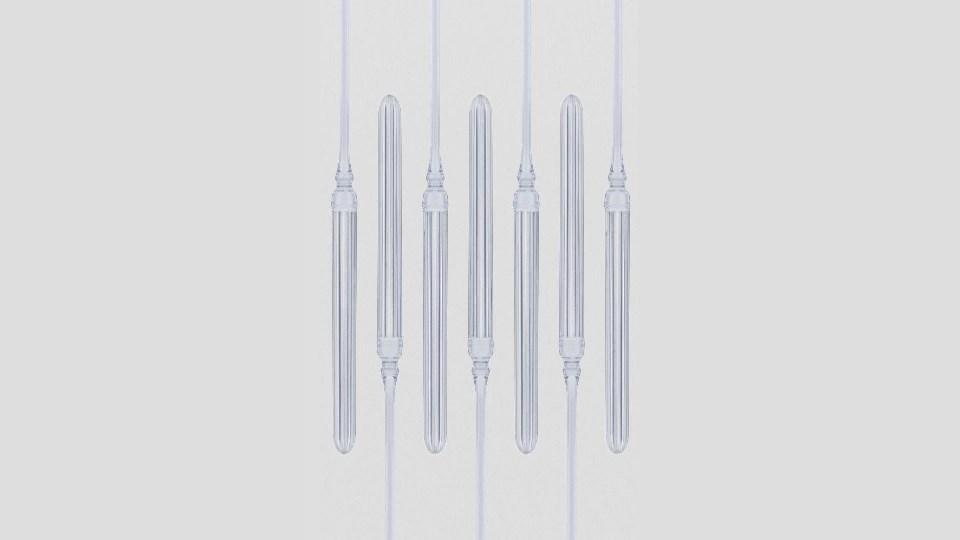

NUS inventors have played a key role in the global fight against the COVID-19 pandemic in myriad areas. One area of contribution: the nasopharyngeal (NP) swab, a flexible stick with a tip section that is carefully designed to collect and retain nasopharyngeal fluid samples from patients, to test for viral DNA.

The Accuswab® features a tip section designed with small blades that extend parallel to its longitudinal axis. When the swab is rotated, the perpendicular motion of these edges will scrape and collect the necessary fluid from the nasopharynx area.

The NUS-developed NP swab, IM2, has recently reached another milestone by receiving CE certification, which allows it to be marketed internationally.

Developed by Professor Freddy Boey, NUS Deputy President (Innovation & Enterprise), IM2 features a tip section designed with small blades that extend parallel to its longitudinal axis. When the swab is rotated, the perpendicular motion of these edges will scrape and collect the necessary fluid from the nasopharynx area. A clinical study by the National University Hospital revealed that the IM2 swab was comparable in terms of safety and performance to the standard-of-care swabs used to test for COVID-19.

In order to scale up production rapidly, IM2 swabs were designed in a way that could be injection moulded, which is faster and more cost-effective than 3D printing. 3D printing is another manufacturing process that has also been used to quickly manufacture NP swabs to meet the global shortage. Initially, the 3D printing process was faster, as it did not require one to make a mould. However, once a mould is made, injection moulding proves to be the more cost-effective process, with a considerably faster cycle time for mass manufacturing.

“Injection moulding as a manufacturing process is inherently faster than 3D printing as multiple units of the swabs can be produced in a given cycle. Several hundred swabs can be produced in a few minutes using the moulding process,” shared Prof Boey.

“The use of injection moulding ensures a secure source to supply high volumes of swabs at a low cost, to meet the needs of our community and beyond. This is crucial in our continued fight against the pandemic.”

Xem chi tiết tại đây